Wednesday, November 20, 2019

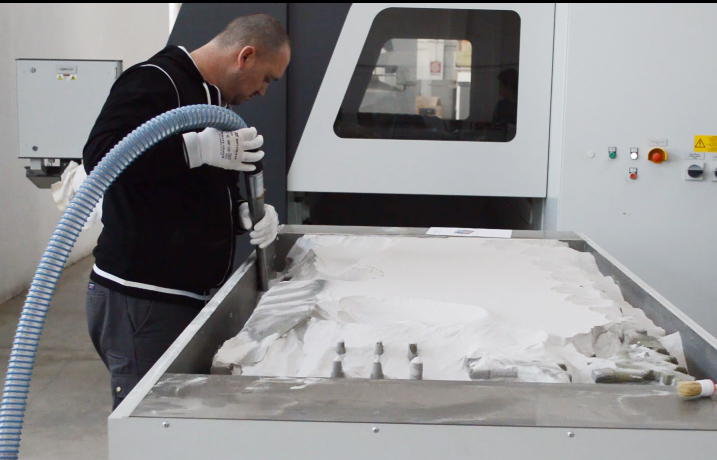

3D printing: Pharaon hoovers ensure maintenance and safety

Specialised in industrial cleaning equipment, the Pharaon company develops specific solutions dedicated to the maintenance of 3D printing and additive manufacturing machines. Easy to use, these hoovers are available in different models depending on the materials used and the work environment.

To meet the need for vacuuming in sensitive environments, the company based in Brillon, near Lille, has developed hoovers for additive manufacturing professionals. "We have developed the INERT range, designed for the suction of powders used in additive manufacturing," informs Anthony Veriez, sales manager.

Launched in October 2018, this range enables the suction of conductive, flammable and potentially explosive powders. "The hoovers in this range are equipped with a dust filtration and inerting system consisting of an oil bath that will neutralise and filter them. Whether it's titanium, aluminium or any other powder, it will be inert and can be disposed of safely.

Hygiene, safety and cost reduction

Used to clean the production chamber before the next cycle, during mass production or when changing prototypes, these hoovers were designed with the main stakeholders: the 3D printer manufacturers. "Our R&D teams worked for a year to develop such a neutralising system, enabling us to limit the risks and thus offer the best hygiene, safety and environmental conditions to the operators.

ATEX certified, the hoovers have been designed to facilitate maintenance. Sold to 3D printer users and manufacturers, they are mainly used for cleaning floors, emptying the production room, cleaning machines and workstations and cleaning finished products.

More information: www.pharaon.fr

Editor: Nadia Daki