Monday, April 26, 2021

Photocentric's new DPP (Daylight Printing Polymer) technology

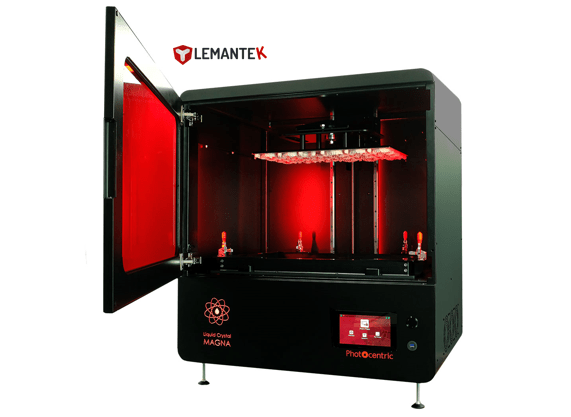

Can you introduce us the machine and describe us the technology used?

The highlighted technology is Photocentric's DPP (Daylight Printing Polymer): thanks to its LCD screen (daylight) with a 4K resolution, it allows a resolution of 137 μm (X,Y) and up to 25μm (Z) to produce mass-produced or large parts with printing speeds of up to more than 13mm per hour.

The Photocentric range of resins offers a wide range of technical materials that can meet many functional needs:

- Prototyping and engineering

- Modelling and architecture

- Tooling (moulding, gripping, fitting)

- Models (foundry, low pressure casting)

- Mass production of thermoset parts (dental models, etc.)

What are the strengths of this technology?

Fast printing speed (height of 13.3 mm/h)

Large printing volume (510 x 280 x 350 mm)

Smooth surface ready for painting,

High level of detail (resolution)

Low production cost from 50€/kg of resin

Can you give us some concrete examples of customers who use this machine?

We can mention for example the 3D production of custom orthopaedic models as a replacement for conventional 3 axis CNC. The production capacities are

1000 pairs of models per year in full flexibility.

Production of dental models for the thermoforming of gutters (more than 60 models/tray, every 1h30)

Production of foundry models up to 1.5m for sand moulding.

Production of thermoplastic micro-series parts (limited series product, after-sales service part)

For more details: download the brochure

Contact: Guillaume Cabrié - guillaume.cabrie@lemantek.com

Nous pouvons citer par exemple la production 3D des modèles orthopédiques sur-mesure en remplacement des CNC 3 axes conventionnels. Les capacités de production sont

supérieures à 1000 paires de modèles par an en toute flexibilité.

supérieures à 1000 paires de modèles par an en toute flexibilité.

Production de modèles dentaire pour le thermoformage de gouttières (plus de 60 modèles/plateau, tous les 1h30)

Réalisation de modèles de fonderie jusqu’à 1m50 pour le moulage sable.

Réalisation de pièces en micro série thermoplastique (Produit en série limité, pièce de SAV)

Pour plus d’information : téléchargez la brochure

Contact : Guillaume Cabrié – guillaume.cabrie@lemantek.com

Contact : Guillaume Cabrié – guillaume.cabrie@lemantek.com