Monday, March 25, 2019

How to turn a liquid into a solid with photons: the bright idea of Berkeley researchers

Star Trek invites itself into 3D printing: In the universe of this fiction, the "replicator" is an energy/matter converter capable of materializing any object whose structure has been pre-registered in a database.

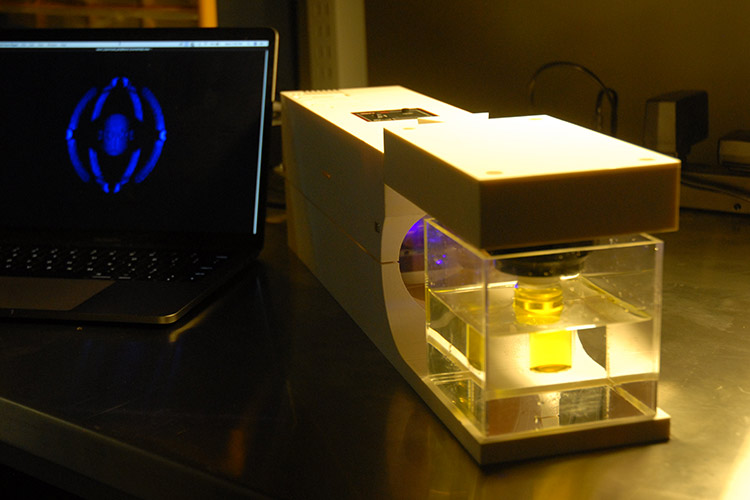

Researchers at the University of Berkeley (USA), perhaps inspired by this cult series, have just developed a new 3D printing process that can create objects thanks to a computer-controlled projector that sends two-dimensional images through a photosensitive gel. In other words, this printer uses light to transform a liquid material into a solid object in just a few minutes. They have therefore logically nicknamed their invention "the replicator"!

This new technique, more seriously named "volumetric additive manufacturing by tomographic reconstruction", allows to create objects in a few minutes, based on a technology used in radiotherapy which delivers radiation doses in a precise way to cancer patients. They have thus created a machine capable of printing an entire object by avoiding the "classic" method of 3D printing by successive layers.

The process works via a computer-controlled projector that sends images of the object to be created from different angles, which are synchronized with the rotation of the material. The California researchers used a light-curing resin and two light sources at different wavelengths. When the photons, which arrive at different angles, cross each other, the gel hardens. The object then appears solid and whole.

The 3D printer works by shining the changing patterns of light through a rotating vial of liquid. A computer algorithm calculates the exact patterns of light needed to shape a specific object.

(UC Berkeley photo by Hayden Taylor)

Smoother, more complex and faster!

Accuracy is in the range of 0.3 millimeters using acrylic polymers. The machine can also use a gelatin methacrylate hydrogel (GeIMA) to create flexible structures with exceptionally smooth surfaces.

This process would allow a wider choice of resins than conventional techniques that require a certain viscosity to deposit the resin in a liquid form. This method could indeed use materials with a very high viscosity.

Another important advantage is that it is possible to insert objects inside the gel and print around it. As a demonstration, the researchers created a handle around a screwdriver shaft. We deduce that this same technique could also be used to encapsulate sensitive electronic components?

The system would finally allow a continuous printing at a speed of about two meters per hour against only a few millimeters to a few centimeters for conventional systems.

For more information:

https://news.berkeley.edu/2019/01/31/new-3d-printer-uses-rays-of-light-to-shape-objects-transform-product-design/

Editor : Anne DE LANSALUT